+86-18898486814

sales@lcrapid.com

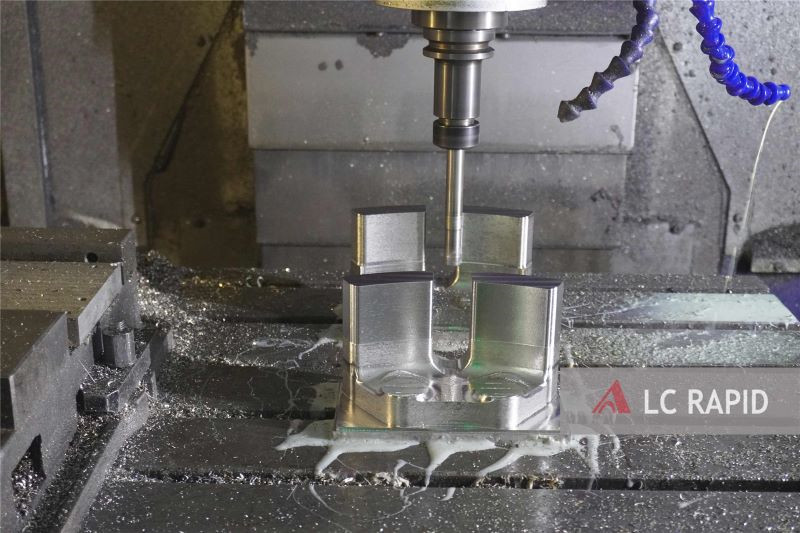

In the CNC milling service, the rotation direction of the milling cutter is generally unchanged, but the feed direction is changed, which causes two common phenomena in milling processing: down milling and up milling.

The cutting edge of the milling cutter is subjected to an impact load every time it cuts. In order to successfully mill, you must consider the correct contact form between the cutting edge and the material when cutting in and cutting out. In the milling process, the workpiece is fed in the same or opposite direction along the rotation direction of the milling cutter, whether down milling or up milling is used, will affect the cutting in and out of milling.

1. The golden rule of CNC milling: from thick to thin

When milling, the formation of cuttings must be considered. The decisive factor for the formation of cuttings is the position of the milling cutter. We must strive to form thick cuttings when the cutting edge cuts in and thin cuttings when the cutting edge cuts out to ensure a stable milling process. Remember that the golden rule of CNC milling service is "from thick to thin" to ensure that the cutting thickness is as small as possible when the cutting edge is cut out.

2. Down milling

In down milling, the cutting tool feeds in the direction of rotation. As long as the machine tool, fixture and workpiece permit, down milling is always the preferred method.

In edge down milling, the cutting thickness will gradually decrease from the beginning of cutting, and eventually reach zero at the end of cutting, which prevents the cutting edge from scratching and rubbing against the surface of the part before participating in the cutting.

A large cutting thickness is beneficial, as the cutting force tends to pull the workpiece into the milling cutter, keeping the cutting edge cutting. However, because the milling cutter is easily pulled into the workpiece, the machine tool needs to deal with the table feed gap by eliminating backlash. If the milling cutter is pulled into the workpiece, the feed will increase unexpectedly, which may result in excessive cutting thickness and fracture of the cutting edge. In these cases, consider using up milling.

3. Up milling

In up milling, the feed direction of the cutting tool is opposite to the direction of rotation.

The cutting thickness gradually increases from zero until the end of cutting. The cutting edge must be forcibly cut in, so the scratching or polishing would happen due to friction, high temperature, and frequent contact with the work hardened surface caused by the front cutting edge, all of which will shorten the tool life.

The thick cuttings and higher temperature generated when the cutting edge is cut out will cause high tensile stress, which will shorten the tool life, and the cutting edge will usually be damaged quickly. It can also cause the cuttings to stick or weld to the cutting edge, which will then carry it to the starting position of the next cut, or cause the cutting edge to break instantaneously.

The cutting force tends to push the milling cutter and the workpiece away from each other, and the radial force tends to lift the workpiece from the table. When the machining allowance changes significantly, up milling may be more advantageous.

4. Workpiece fixture for CNC milling

The feed direction of the tool in the CNC milling service puts different requirements on the workpiece fixture. During up-milling, it should be able to resist lifting force. During down milling, it should be able to resist downforce.