+86-18898486814

sales@lcrapid.com

Vacuum Casting: It is a craftsmanship specially used for making exquisite hand model and small batch copying, and it is widely used for sample preview of injection molded products. The commonly used plastic materials for vacuum casting applications are PP and PA. The color selection and strength of the molded parts are very flexible, which is very suitable for product designers to make customized products.

Silicone vacuum casting mold is specially used for large-scale reproduction of resin, ceramics, plastics, plaster, cement, candles, soap and other crafts.

(1) The volume of the product should be considered in the process of silicone vacuum casting (the weight of a single part is recommended to be within 2.5kg), because when vacuum casting is used as a product model, the larger the volume of the product, the greater the cooling shrinkage ratio, and the time consuming is getting longer.

(2) Try to avoid sharp product modeling.

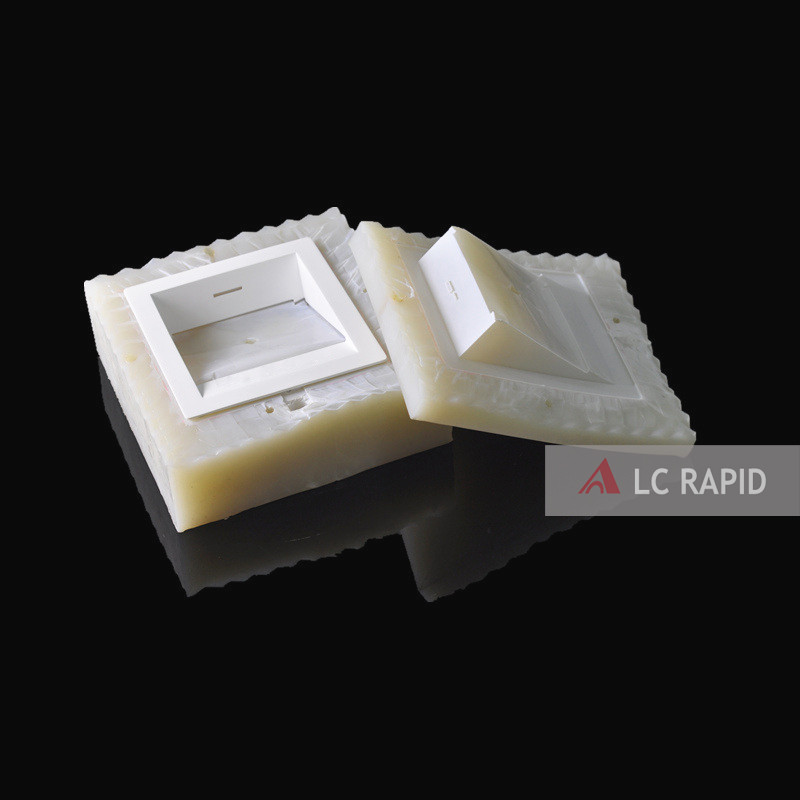

Preliminary preparation: use a single finished product to remake two vacuum casting silicone molds

Step 1: Combine the two pre-prepared silicone molds and place them in an environment of 65°-70°. The joints of the two silicone molds will begin to melt until they are seamlessly connected.

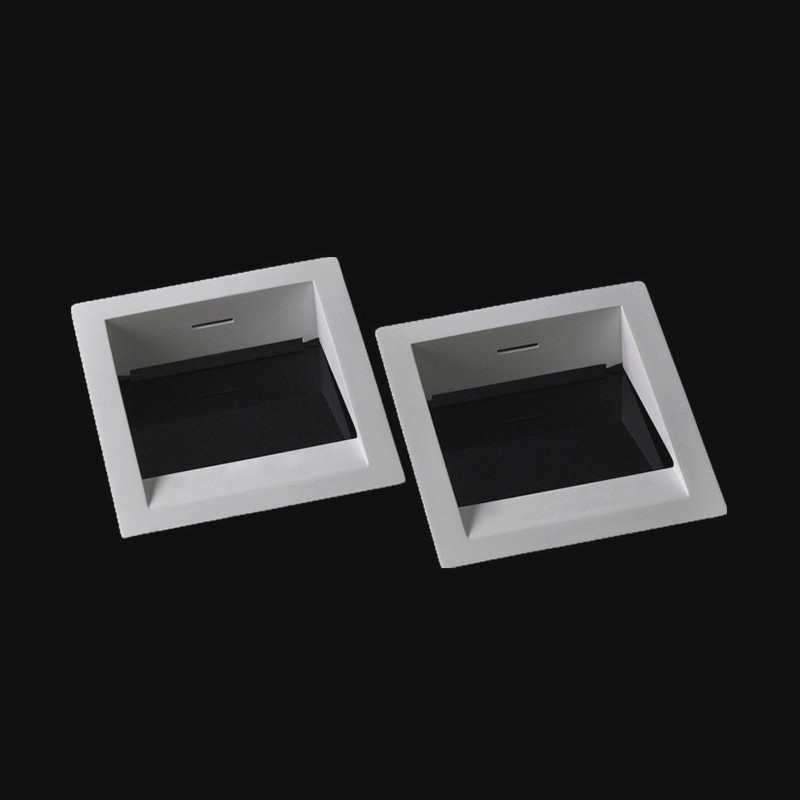

Step 2: Evacuate the air in the vacuum casting silicone mold, pour the liquid PUR into the drainage tube until the cavity of the mold is filled. Then cool it down (45 minutes-4 hours).

Step 3: Cut two pieces of silicone mold, take out the finished product, wait for trimming and polishing.

1. The mold is complex but excellent with good mold effect;

2. High mold frequency and long mold life after vacuum mould casting;

3. Flame resistance and high temperature resistance, especially for unsaturated resin handicrafts and glass resin handicrafts;

4. The shrinkage rate is low, and the silicone mold will not be deformed;

5. High tear strength, not easy to tear during demolding.