+86-18898486814

sales@lcrapid.com

With the help of automation and robotics, the automotive industry has made continuous improvement. The automotive production and design have been greatly improved. CNC machining is the latest automation technology that changes the automotive manufacturing process.

Computer numerical control (CNC) machining is a computer-controlled manufacturing process that can produce precision parts using many different materials, from plastic to metal. To create parts, CNC machines send computerized instructions to power tools such as lathes or drills. And the tool turns a piece of material into a finished product according to the instructions.

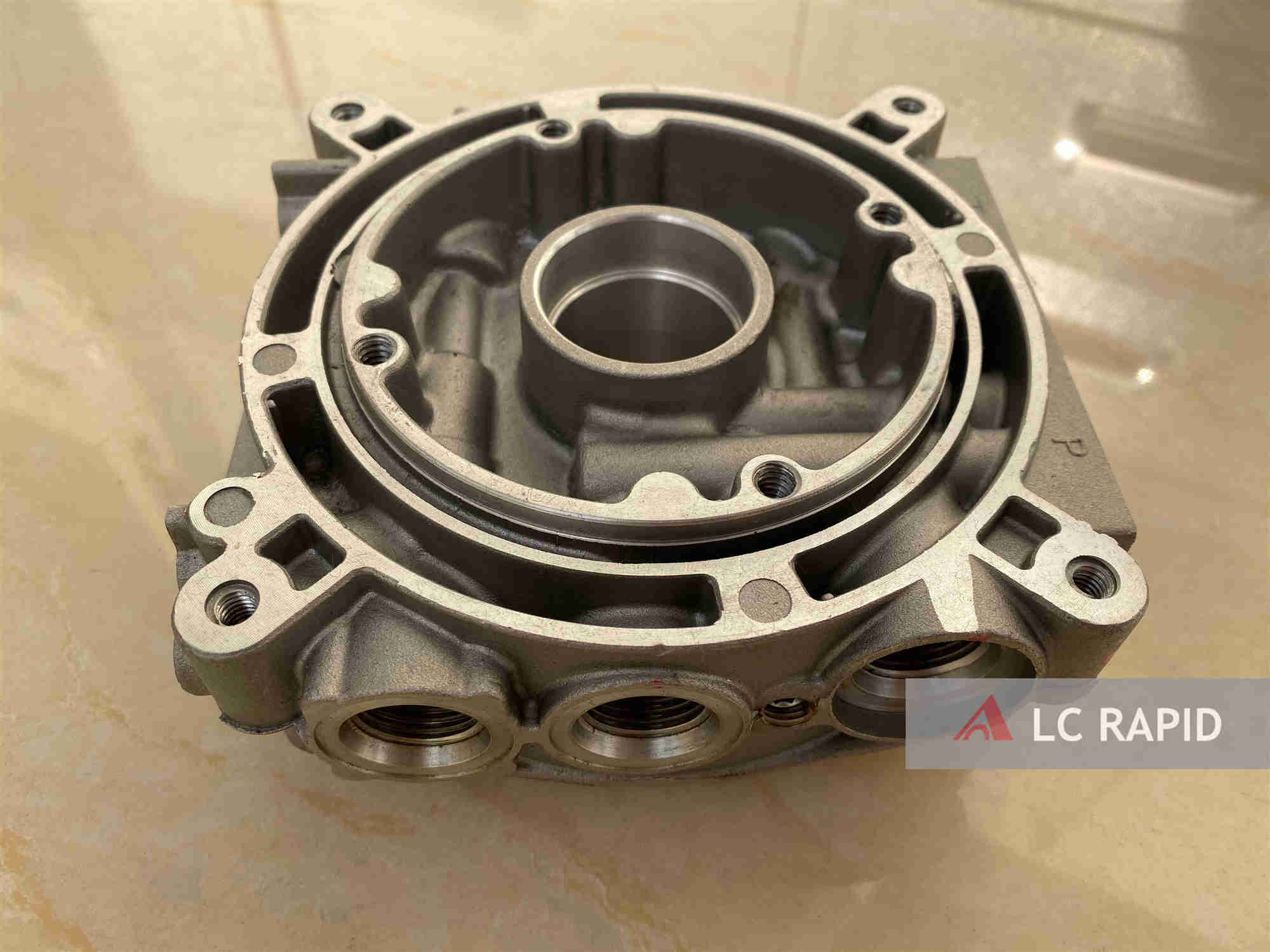

CNC machining can be used in automobile production to manufacture engine parts, interior and headlight lighting, suspension parts, carburettor housings, exhaust parts, etc.

CNC machining is also called numerical control machining. Before programming, the technology analysis should be conducted for processed parts, the processing plan should be drawn up, the appropriate tool should be selected, and the cutting amount should be determined. In programming, some technology issues such as tool setting point and processing route need to be dealt with. Therefore, the technology analysis in programming is very important.

When processing parts on ordinary machine tools, technological procedures or process cards are used to specify the operating procedures of each process, and the operator processes the parts according to the steps specified on the process card. When machining parts on a CNC machine tool, all the process, process parameters and displacement data to be processed must be compiled into a program, which is used to control the machining of the machine tool.

LC RAPID MANUFACTURING Co., Ltd. can offer custom cnc machining, stainless steel cnc machining services, rapid prototyping cnc machining, and other services, which is famous within the industry.

The CNC machining process is basically the same as the machining process of ordinary machine tool in principle, but the entire process of CNC machining is carried out automatically, so it has its own characteristics:

1. The content of CNC machining process is complicated

This is because CNC machine tools are more expensive than ordinary machine tools. It is not economically cost-effective to conduct simple processes with it. Therefore, more complicated processes are usually arranged on CNC machine tools, even those that are difficult to complete on ordinary machine tools.

2. The arrangement of CNC machining steps is more detailed

This is because the issues that do not need to be considered in the processing technology of ordinary machine tools, such as the arrangement of steps in the process, the tool setting point, the tool change point and the determination of the processing route, cannot be ignored when programming the processing technology of CNC machine tool.

3. It relies on procedures to complete all technological processes.

4. The CNC machining program is the mandatory document of the CNC machine tool.

5. The CNC machine tool is controlled by program instructions, and the whole process of CNC machining is carried out automatically according to the program instructions.

6. The CNC machining program not only includes the technological process of the parts, but also includes the process parameters necessary to complete the process, such as the cutting amount, the feed route, the tool size number, and the motion process of the machine tool.

7. CNC machining has high efficiency, high machining accuracy, low labor intensity, and strong adaptability to different workpieces.

There are many advantages in using CNC machining in the automotive industry, including:

1. CNC machining can increase the production speed

Compared with traditional machining, CNC machining boasts less production time. Since it is an automated process, there are no human factors like fatigue that can be overcome. Computer instructions can also be repeated as many times as needed, so this process is most suitable for rapid production of large numbers of parts.

2. Accuracy

Through the automated computerized process of CNC machining, the possibility of production errors is greatly reduced. The automotive industry requires precise tolerances, and therefore, the level of high precision is of utmost importance.

3. Repeatability

Since CNC machining operations can be repeated as many times as needed, it is particularly useful for mass production of single parts. And because the batches of parts must be consistent, its repeatability is a major advantage in the automotive industry.

4. Simplified process

CNC machines can handle all production steps of a simplified process, so employees can focus on innovation and design.

5. Reduce costs

The high efficiency of CNC machining can save the company costs.

In order to complete your project perfectly, it is very important to choose a reliable CNC machining manufacturer, because not all companies can complete the same quality of work. As a full-service CNC machining manufacturer, we can handle your machining project from start to finish, thus saving you time and money, and reducing trouble. To learn more about our CNC machining capabilities, welcome to consult LC RAPID MANUFACTURING Co., Ltd.