+86-18898486814

sales@lcrapid.com

Thermosetting plastic injection molding uses a screw or plunger to reduce the viscosity of the polymer in a heated barrel (120~260°F), and then inject it into a heated mold (300~450°F). Once the material is full of the mold, it is kept under pressure. At this time, chemical cross-linking occurs, making the polymer hard. The hard (ie solidified) product can be ejected from the mold while it is hot, and it cannot be reshaped or remelted.

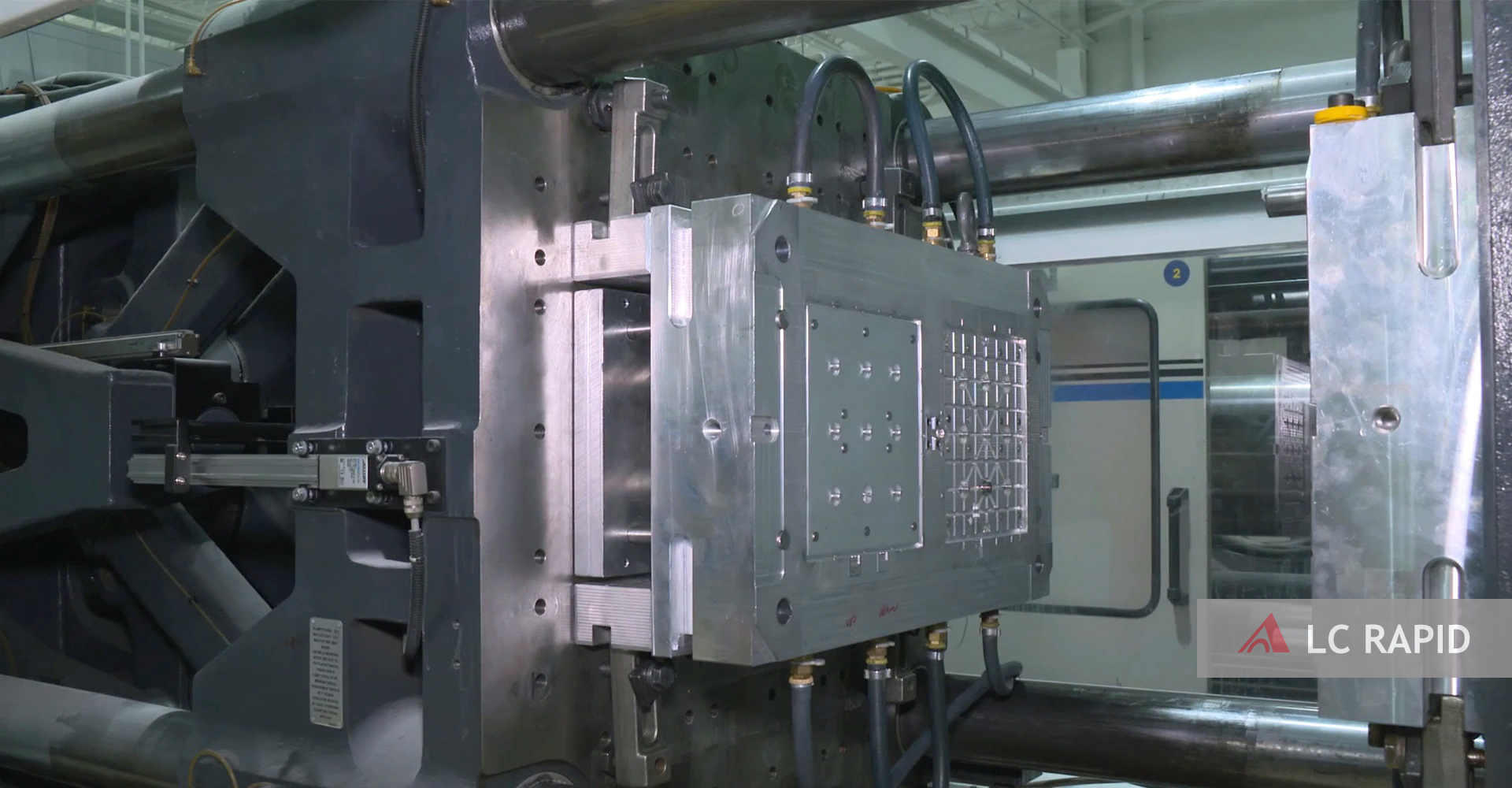

The injection molding equipment has a hydraulic drive mold clamping device to close the mold, and an injection device that can transport materials. Most thermosetting plastics are used in granular or flake formation and can be fed into the screw injection device from a gravity hopper. When processing polyester monolithic molding compound (BMC), it is like a "bread dough" in which the feed piston is used to press the material into the threaded groove.

The processed polymers using this process are (arranged according to the amount used): phenolic plastics, polyester monolithic molding compounds, melamine, epoxy resins, urea-formaldehyde plastics, vinyl ester polymers and diallyl phthalate (DAP).

Most thermosetting plastics contain a large amount of fillers (up to 70% by weight) to reduce costs or improve their low shrinkage properties, increase strength or special properties. Commonly used fillers include glass fiber, mineral fiber, clay, wood fiber and carbon black. These fillers can be very abrasive and produce high viscosities, which must be overcome by processing equipment. As one of the top injection molding companies, we will provide you the best serivce in rapid injection molding prototyping, small or big volume..

1. The purpose of the injection molding process

Both thermoplastics and thermosets will reduce viscosity when heated. However, the viscosity of thermosetting plastics increases with time and temperature because of the chemical cross-linking reaction.

The combined result of these effects is that the viscosity exhibits a U-shaped curve with time and temperature. The operation of filling the mold is completed in the lowest viscosity area, which is the purpose of the thermosetting injection molding processing, because the pressure required for the material to be molded into the mold shape is the lowest at this time. This also helps to minimize damage to the fibers in the polymer.

2. The process of injection molding process

Injection molding process: the screw is used to make the material flow through the heated barrel, and water or oil is circulated in the jacket around the barrel.

The screw can be designed according to different types of each material. The material is slightly compressed to remove air and heated to obtain a low viscosity. The flow of most thermosetting materials here is quite good.

The operation to make the material enter the mold is to stop the screw rotation and use the hydraulic pressure to push the screw forward at a high speed, so that the plasticized low-viscosity material is pressed into the mold.

This fast flow requires filling the cavity within 0.5 seconds, and the pressure needs to reach 193MPa. Once the membrane cavity is filled, the high-speed flow of materials generates greater frictional heat to accelerate the chemical reaction.

Once the cavity is filled, the injection molding pressure will drop to the holding pressure of 34.5-68.9MPa. The holding pressure is maintained on the material for 5-10 seconds, then the pressure is relieved, and then the next cycle of plasticizing phase begins.

This material is kept in the hot mold until it hardens, then the clamping device is opened and the product is ejected. The product can be slightly uncured and a little soft when it is first ejected, and the final curing can be completed by the heat retained in the product within 1 or 2 minutes after being taken out. The entire production cycle of thermoset products is 10 to 120 seconds, depending on the thickness of the product and the type of raw material.

Many different and specialized technologies are used to improve the quality and reproducibility of products. In view of the fact that some thermosetting polymers generate gas when heated, there is often a degassing operation after the mold is partially filled. In this step, the mold is opened slightly to allow the gas to escape, and then you can quickly close it to refill the remaining material. And then the further thermoplastic powder coating can be taken into consideration.

3. Features of injection molding process

Injection molding provides relatively high strength, relatively easy dimensional control, and improved surface condition (appearance). This is due to the use of a mold with a retractable film cavity and a film core. In the injection molding process, the mold can be open 1/8-1/2, and then be quickly compressed.

The integral molding compound made of glass fiber, filler and polyester unsaturated resin can be molded through the machine equipped with other special devices.

Connect the piston feeder to the barrel to force the feed, and then it can be operated in two different ways:

(1) With a traditional reciprocating screw, the screw pushes the material forward while mixing and heating. This requires a check valve at the end of the screw to prevent the material from flowing back to the screw thread since the viscosity of the material is very low.

(2) A plunger or piston is used to press the material into the mold cavity. The plunger is often used for materials that contain more than 22% of the weight of glass fiber because it does less damage to the fiber and can make the materials obtain higher strength.

Another processing method that was first applied to injection molding of thermoset plastics was compression molding and die casting. Compared with them, the advantages of injection molding methods are: injection molding is faster; the process is automated; product changes are less; lower labor costs; and high production capacity.