+86-18898486814

sales@lcrapid.com

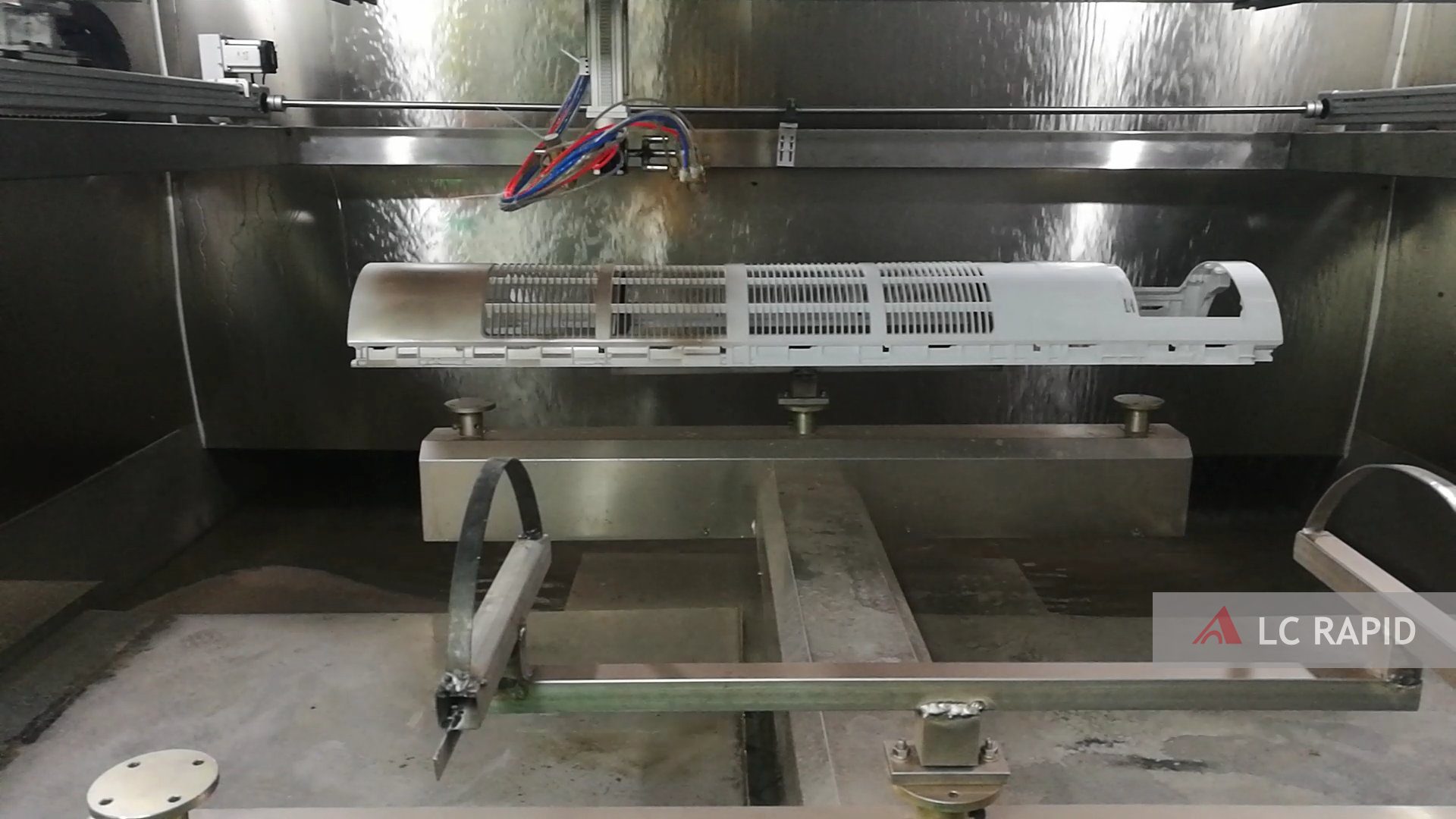

Do you know what sheet metal fabrication is? Sheet metal fabrication is a professional term in the industry. It refers to the metal sheet processed into various specifications and shapes that we need, which has many applications, suach as auto or aerospace sheet metal fabrication. Sheet metal fabrication needs to go through methods and processes such as cutting and blanking, punching, bending and forming, and then splicing and forming, so as to obtain the sheet metal processed products we need. For example, our air conditioner sheet metal shells are processed products of sheet metal shells.

Commonly used materials for industrial sheet metal fabrication include cold-rolled sheet, hot-rolled sheet, galvanized sheet, copper, brass, red copper, beryllium copper, aluminum sheet, stainless steel, etc. Generally, the selection of materials should be considered from the overall use and cost of the product, and different materials should be selected according to the different uses of the product.

The air conditioner sheet metal shell is one of our many sheet metal fabrication products. It has the characteristics of light weight, good shape and corrosion resistance. The commonly used materials of the sheet metal chassis processing products we produce are as follows:

1. Cold rolled sheet SPCC

SPCC refers to steel ingots that are cold-rolled into steel coils and flat plates with a certain thickness.

2. Galvanized sheet SECC

The substrate of SECC is ordinary cold-rolled steel coil, which is made into galvanized products through degreasing, pickling, electroplating and subsequent treatment in the electro-galvanizing production line.

SECC has the mechanical properties and similar processability of general cold-rolled steel, and also has superior corrosion resistance and is conducive to decorative appearance.

It is highly competitive and replaceable in the markets of electronic products and home appliances. For example, SECC is commonly used in computer cases.

3. Hot-dip galvanized sheet SGCC

Hot-dip galvanized steel coil refers that: the semi-finished products of hot-rolled pickling or cold-rolling are cleaned, quenched, and immersed in a molten zinc bath at a temperature of about 460℃, so that the steel sheet is coated with a zinc layer, and then they are tempered, flattened, and treated by chemical lotion.

4. Stainless steel SUS304

It is one of the most widely used stainless steel. Because nickel-containing steels are more resistant to corrosion and heat than chromium-containing steels, it has very good mechanical properties, no heat treatment hardening, and no elasticity.

The air conditioner shell is also a sheet metal fabrication product, and the main appearance parts are generally sheet metal parts and plastic parts. During the use of air conditioner shell metal materials and plastics, due to the contact with the surrounding environment and the action of light, heat and oxygen, the metal surface will undergo chemical or electrochemical corrosion. Polymer materials will undergo photo-aging or thermal aging, which will cause the surface of the material to deteriorate, wear out and be damaged.

In order to ensure a certain life span and beautiful appearance of these metal and plastic parts, the surface protection and decoration of metal and plastic materials must be carried out.

The sheet metal fabrication parts of the air conditioner appearance mainly made from cold-rolled steel plates and electro-galvanized steel plates. The coating methods include cathodic electrophoresis and electrostatic spraying, and some directly use overmolded steel plates. These three methods have similarities and have their own characteristics.

1. The characteristics of cathodic electrophoresis: the paint film is flat and smooth, wih no rust spots, no obvious pinholes, shrinkage holes, flow marks and particles, and has strong adhesion that is not easy to fall off.

2. The characteristics of electrostatic spraying: the characteristics are very similar to the characteristics of cathodic electrophoresis, but its impact resistance is weaker than that of cathodic electrophoresis .

3. The characteristics of the overmolded steel plate: the surface of the plate is smooth and bright, without obvious bubbles, impurities, scratches, wrinkles, convexities and other defects, and the pattern is the same as the sample plate. It is often used in the panel of the outdoor unit of the cabinet.

With the improvement of sheet metal chassis processing technology, sheet metal chassis products are more and more widely used in life. Do you know that the outer shell of the air conditioner is also a sheet metal processed product? After the air conditioner sheet metal shell is processed and formed, it undergoes a series of surface treatments to become the beautiful air conditioner shell we see now.

A ductless mini-split air conditioner consists of indoor and outdoor parts, and the surface treatment methods of the sheet metal processing shells are different for different parts of the air conditioner.

1. For the surface treatment process of the outdoor unit shell and base of the split air conditioner, and the sheet metal processing of the indoor cabinet body of the cabinet unit, we generally use the electrostatic spraying process.

Its specific process is: first degrease the surface of the steel plate. After level-2 water washing, surface adjustment, phosphating, level-3 water washing, drying, electrostatic spraying, cure and form it.

2. For the surface treatment process of the panel sheet metal processing of the cabinet unit indoor unit, the coated steel plate technology is adopted.

Its specific process is to first degrease the surface of the steel plate, go through two-level water washing, surface adjustment, three-level water washing, passivation, drying, primer spraying, drying, and surface coating forming. Its characteristic is that the board surface is smooth and bright, without obvious bubbles, impurities, scratches, wrinkles, drums, convexities and other defects, and the pattern is the same as the sample pattern.

The above is the surface treatment method and coating of sheet metal fabrication shells of air conditioners.