+86-18898486814

sales@lcrapid.com

The aluminum profile production and processing process includes cutting, opening, tapping, slot milling and installation. As the key production process, the aluminum profile CNC cutting has an extraordinary effect. A piece of aluminum profile has a length of 6 meters, and generally all of them must be cut before they can be assembled and applied. The CNC plasma cutting of aluminum profiles is carried out based on the production and processing engineering drawings, and the cutting accuracy must be ensured so as not to harm the subsequent applications. At the same time, it also fully saves labor costs, saves the enterprise operating costs, promotes enterprise standardized production, and improves product quality and good rate.

The density of aluminum alloy for automobiles is only 1/3 of that of steel, and it is lightweight, recyclable and easy to form. Aluminum can absorb a lot of energy when it collides, which can improve the safety of the car while reducing weight.

Lightweight and high safety have made automotive aluminum alloy battery shells the mainstream of power battery shells. The battery shell made of aluminum alloy is thinner and lighter than the steel shell. In addition, once the battery explodes, the lithium battery aluminum shell is also weaker than the steel shell in explosiveness, and the damage caused by the aluminum shell power battery is relatively lower. When producing aluminum alloy battery shells for new energy vehicles, precision plasma cutting is often used.

The battery box, liquid-cooled plate, anti-collision beam, shock absorber, new energy vehicle electrical bracket, CCB instrument panel bracket and lower body aluminum profile parts in new energy vehicles can all be made of aluminum alloy. For example, the battery box of FAW-Volkswagen cars adopts cnc plasma cutting service to improve the performance and quality of the car.

This kind of aluminum alloy sheet after CNC cutting has the following characteristics:

1) Low density

2) Excellent thermal conductivity

3) Good damping and shock absorption

4) Good corrosion resistance

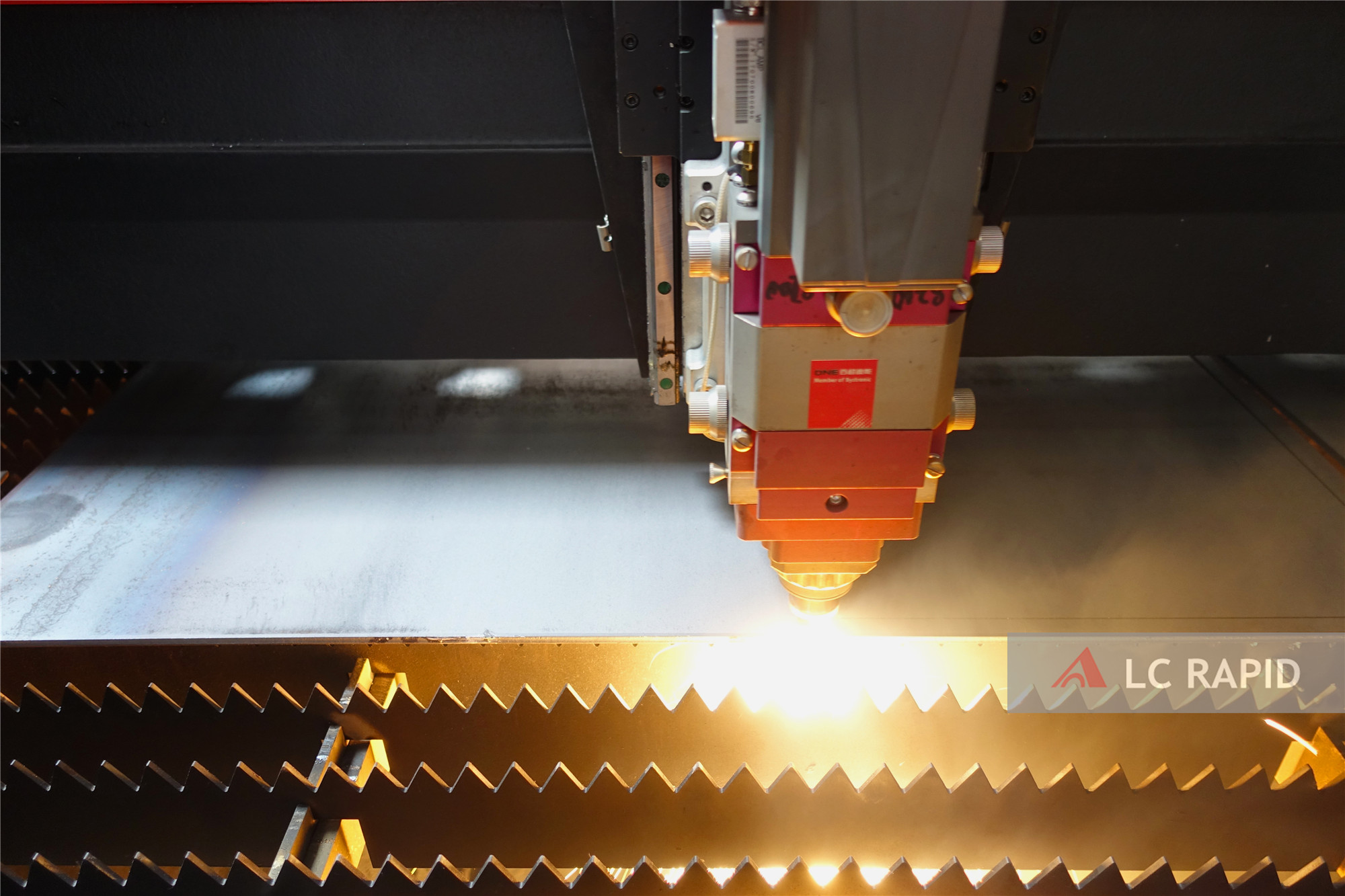

Laser cutting

(1) Cutting quality: excellent inclination angle and small area affected by heat. Basically no slag; excellent fine cutting effect can be achieved under the narrowest bend condition;

(2) Production capacity: The cutting torch can be quickly disengaged, which improves the production efficiency. It is extremely fast when cutting metal materials with a thickness of less than 6mm. The thicker the metal, the lower the speed, the thicker the metal, and the longer the perforation time. Generally laser cutting is used in non-metal cutting metal, only high-precision laser cutting is used.

Plasma cutting

(1) Cutting quality: excellent inclination angle, small area affected by heat, basically no slag, good to excellent fine cutting effect

(2) Production capacity: when cutting metal materials of various thicknesses, the speed is extremely fast, and the perforation speed is extremely fast

In the future, with the continuous development of CNC laser cutting services, the cut aluminum alloy sheets will have higher strength, more and more complex cavities, thinner walls, higher welding performance and lower costs.

LC Rapid can provide customers with router cutting services, CNC laser cutting services and cnc plasma cutting services. In order to fully meet customer needs, we can also customize CNC cutting. Please feel free to contact us and we will provide you the best quality service.