Precision Sheet Metal Manufacturing Material

| Aluminum | Stainless steel | Mild steel | Copper |

| 6061-T651 | 304 | 1018 | C101 |

| 5052-H32 | 316/316L | Galvanized Steel | C110 |

| 301 | 260 (Brass) |

| Aluminum | Stainless steel | Mild steel | Copper |

| 6061-T651 | 304 | 1018 | C101 |

| 5052-H32 | 316/316L | Galvanized Steel | C110 |

| 301 | 260 (Brass) |

Anodizing, an electro-chemical oxidation process of aluminum and other non-ferrous metals. The anodizing film can improve the wear resistance.

Sand blasting is used to blast part surface with abrasive material. Typically, sand blasting is used to remove machine marks, scratches, impurities, serves as a preliminary step that prepares for later painting or anodizing process.

The brushing process is to use abrasive brushes and chemical corrosion to get a unidirectional satin finish. The process can also be used for decoration. Brushing is typically used on stainless steel, copper and aluminum

Polishing is a surface treatment process to yield a glossy surface on metals like stainless steel, aluminum, and copper. It can serves to reduce surface roughness and improve the surface luster.

Sheet Metal fabrication is crucial to the electronics industry in decades. We can make enclosures or other components in aluminum, stainless steel, steel, brass, and copper for electronic products that need to be in rapid turn-around and low cost.

The applications for sheet metal fabrication when it comes to agriculture solutions are virtually unlimited. we offer a range of materials including aluminum, stainless steel, mild steel, and copper for every applications from livestock management, smart sensors, automated crop farming, and watering systems

Sheet metal is the preferred option to fabricate high quality, accurate consumer products for clients with it’s versatile materials and processes. Whether you need video game equipment, a home appliances such as refrigerators, freezers or any other types of consumer goods, our quick-turnaround service can bring your design to market fast with attractive pricing and high quality.

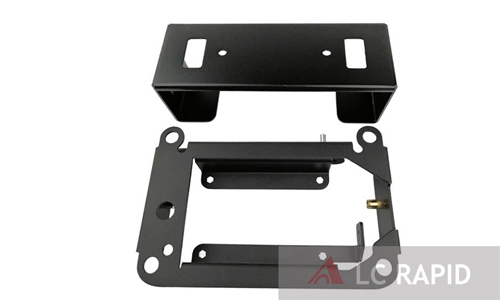

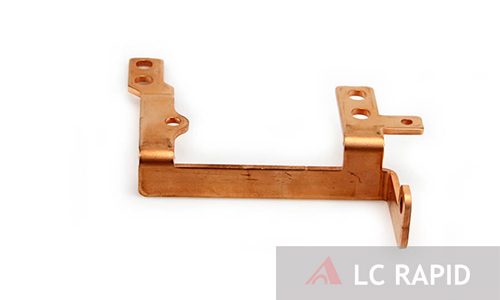

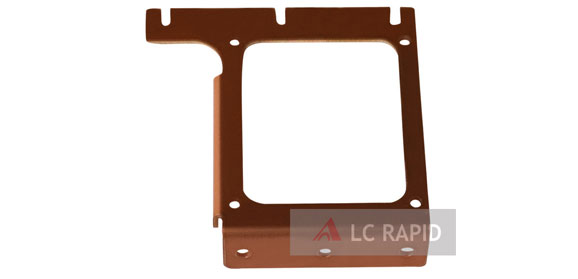

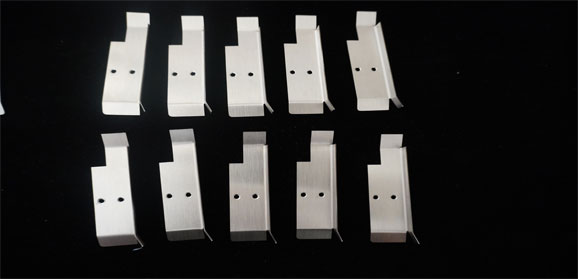

LC Rapid builds many kinds of custom sheet metal brackets, including L brackets, U brackets, Z brackets, and mounting brackets, display brackets, and more. We can also apply electroplating, anodizing, powder coating on sheet metal components, making them have a higher degree of corrosion resistance.

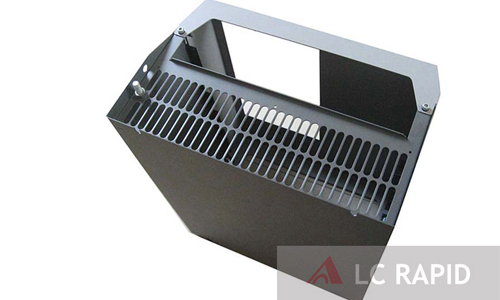

The chassis we fabricate are typically used to as barriers for electrical solutions. Sheet metal is a cost-effective way to fabricate custom chassis, including computer chassis and mechanical testing equipment chassis. All of them are made with precise dimensions and lightweight.

We offer custom sheet metal enclosures, including card cage enclosures, computer enclosures, rack mounts enclosures, and more.