+86-18898486814

sales@lcrapid.com

In no industry is high quality, precision, and safety more critical than the medical industry. At LC Rapid, we utilize our massive range of custom manufacturing services including CNC machining, injection molding or a combination of versatile manufacturing methods to ensure clients’ unique requirements can be exceeded. We have been working with medical device companies, from start-ups to fortune 500 for a a lot of complex applications, we also offer perfect solutions for doctors, patients, research institutions and medical students with medical grade materials.

Stainless steel material is a high strength, heat resistant, corrosion resistant material. Machining this material allows us to produce high quality, tight tolerance parts for medical components, instruments, devices, and other applications.

Metal like aluminum has attributes including high electrical conductivity and good plasticity. It is mainly used to produce high quality, tight tolerance products for medical applications.

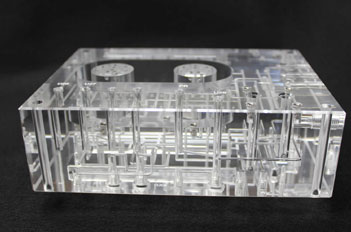

Acrylic has extraordinary light transmission and great smooth surface. It can be used as teeth model for orthodontic treatment, with high clarity and precision.

PEEK has high temperature resistance, which is suitable for applications with sterilization requirements.

Medical Wearable Devices

Surgical Training Models

Dental Implant Devices

Orthopaedics Model

Enclosures and Housings

Ventilators

Prosthetic Components

Scientific Equipment

Medical Trolley

Medical Monitor Instruments

Capabilities for the Medical Industry

CNC Machining

Injection Molding

3D Printing

Sheet Metal Fabrication

Vacuum Casting

Aluminum Extrusion

Carbon Fibre

Pressure Die Casting

Post Processing Used in Medical Industry

Anodizing

Hard Anodizing

Passivation

Electroplating

Powder Coating

Painting

Pad Printing

Vapor Polishing

Insert Installation

Heat Treatment

See all finishing options