+86-18898486814

sales@lcrapid.com

The energy industry is high demanding in both high quality prototypes and high volume production parts with complex geometry. At LC Rapid, we have manufactured a lot of light weight, high quality, and project critical components in custom equipment for energy industry with CNC machining, injection molding or a combination of versatile manufacturing methods. We have the rich experience in meeting high quality standards and accurately understand the need for tailored products and solutions.

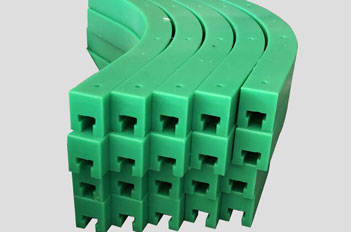

PE is a common thermoplastic resin. PE is an ideal option for concept modeling, functional prototypes with it’s excellent chemical stability, good acid resistance.

POM has good chemical resistance and light weight, making it an preferred option for applications requiring hardness and excellent wear resistance. It is very suitable for the manufacturing of pumps, oil pipelines, power valves, motor gears, and etc.

ABS is used for various applications across the energy industry. It is a thermoplastic with good impact strength and flexibility. ABS can be used to be applied a wide variety of post-processing procedures, including painting, plating, bonding, printing and more.

Aluminum is characterized by high strength to weight ratio, good thermal properties. Aluminum is suitable to produce parts with critical dimensional tolerance.

Jigs and Fixtures

Rotors

Connectors

Flow Meter Parts

Pressure Gauge Pieces

Turbine Nozzles

Control-valve Components

Pump Manifolds

Motors

Capabilities for the Energy Industry

CNC Machining

Injection Molding

3D Printing

Sheet Metal Fabrication

Vacuum Casting

Aluminum Extrusion

Carbon Fibre

Pressure Die Casting

Post Processing Used in Energy Industry

Anodizing

Hard Anodizing

Passivation

Electroplating

Powder Coating

Painting

Pad Printing

Vapor Polishing

Insert Installation

Heat Treatment