+86-18898486814

sales@lcrapid.com

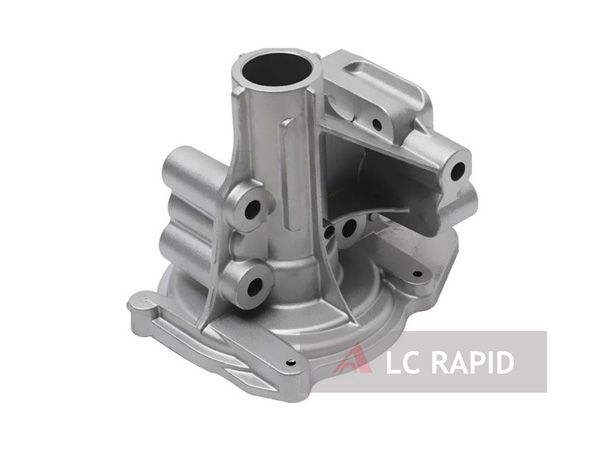

Our custom manufacturing process provides each and every one of our customers with a competitive solution to exceed their requirements, such as rapid prototype, mass production, small batch production, CNC machining, vacuum casting, 3D printing, pressure die casting, injection molding, sheet metal, and aluminum extrusion. No matter how complicated your project may be, we can produce what you need.

LC Rapid has grown to become the preferred supplier of custom parts for businesses, engineers and designers around the world. We now offer manufacturing services including the manufacturing-on-demand to help clients make rapid prototyping and production, CNC machining, vacuum casting, 3D printing (SLA and SLS), carbon fiber, pressure die casting, sheet metal fabrication, aluminum extrusion and injection molding as well as traditional model making and a range of finishing techniques.

Quotes within hours, parts within days

Saving time and money throughout the product life cycle.

Value-added services include assembling, ultrasonic welding, a wide variety of surface finishing processes and packaging.

Offering flexible design options for all your products.

Fast and dependable service.

Accelerating product development and launching products to market faster.

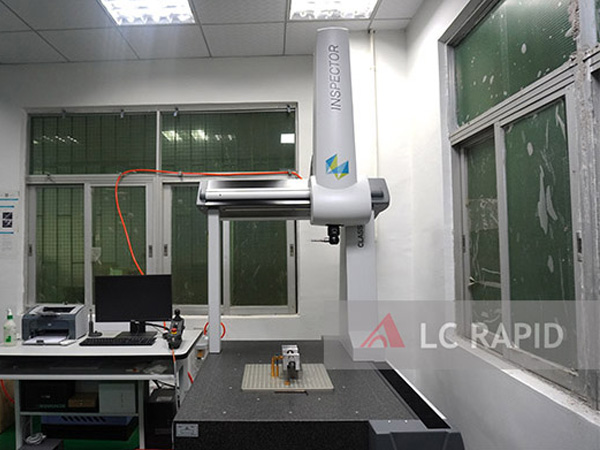

Our state-of-the-art facility is fully equipped to produce your product with zero defects. We own advanced 3-, 4- and 5-axis imported and domestic machines which allow us to produce quick-turnaround prototypes, high precision tools&dies, and great-quality end-use parts in the least possible time. And LC Rapid has the Coordinate Measuring Machine (CMM) with which we can get reliable measurement of complex shapes and surfaces.